PET Fruit Box Thermoforming Machine is our latest developed core product. The machine combines forming, cutting, and stacking into process,which is widely used and acknowdged by most of our customer. It can produce boxes, trays, fast food boxes, dishes, lids, cookies tray, egg tray, mobile phone tray & other blister tray, etc. The machine is completely driven by servo motor with features of stable operation, low noise, high efficiency and quality.

Application Area:

This machine is suitable for production of high demand on all the blister products: blueberry box, fruit box lid, fresh food tray, moon cake tray, disposable fast-food containers, disposable food containers, Instant noodle bowl cover, milk tea lid, coffee lid, beverage cup lid, ice cream cup, jelly cup, packing box, daily necessities blister packaging, medicines and drugs blister packaging, wine packaging, electric equipment blister packaging etc.Bright and clean cutting edge, uniformity of thickness.

| 1 | Suitable Products | Disposable plastic lids,egg trays,clamshell boxes, containers, plates etc. |

| 2 | Suitable Materials | PVC.PP.PET.PS.HIPS.PE.HDPE.PC.ABS.PLA sheet |

| 3 | Thickness Range | 0.1-2.5mm |

| 4 | Stroke Range | 480×480mm |

| 4 | Max. Forming Depth | 120mm |

| 5 | Forming Area | 780mm |

| 7 | Industry Voltage | 380V/50Hz (Three Phase, Four Wires) |

| 8 | Total Power/Actual power consumption | Heating oven Max. 54 KW, usually use 18-30KW/h |

| 9 | Max. Speed | 25-30 Cycles per minute(Depending on material and thickness) |

| 10 | Max. Punching Force | 60 Tons |

| 11 | Air Pressure | 0.7MPa |

| 12 | Air Consumption | > 4000ℓ/min ( with Forming body ) |

| 13 | Cooling Water | Normal Tap Water Recycle Cooling |

| 14 | Noise | <75DB |

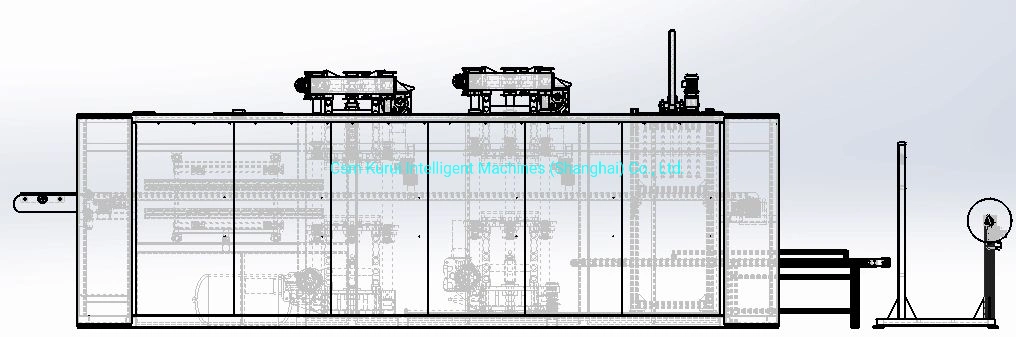

| 15 | Machine Dimension | 9000×2400×2700mm |

| 16 | Machine Weight | 7000kg |

B. Stainless steel pressure roller and automatic feeding (single roll material weight can reach 600-1000KG)

C. The pre-heating device is installed on both sides of the film.

D. There are multiple excessive rollers to ensure that the material will not running when stretching the sheet.

E. The heating furnace has forward and backward functions. It uses photoelectric eyes to detect the sag of the sheet after heating. When it exceeds a certain limit, it provides an alarm and has function of Exit the heating furnace to prevent the sheet from falling out of the heating furnace and causing fire.

Technological process:

Carrying material(cylinder drives the chain to work)---heating(cylinder drives the electric furnace to lift in order to make a proof)---pulling( cylinder drives the chain)----lifting the lower die, falling the upper die(cylinder drives)-vacuum forming(vacuum pump air admission )---cooling(gas drives the spray gun to work, electric machinery drives the air blowing)----drawing of patterns(gas drives)---pulling-cutting---stacking on the line.

Our Services

1. Purchase Service

CSM Kurui(Shanghai) has a specialized and efficient working team. If you are new on the printing and packing area, some samples of your products shown to us, and we will give you professional suggestions of whole work.

2. Installation Service

CSM Kurui(Shanghai) will assigned 1-2 technicians to coordinate installation, set up the machine and training, but all the charges should be paid by buyer.

3. Warranty Service

12 months warranty after installation, if the spare parts is broken in the warranty period, we will send a free replacement parts as free.

Our packaging machines and related products are well packed to ensure that no damage to the products. welcome to tell us your needs and we will arrange all the things from the initial inquiry to the delivery of your chosen port anywhere timely.

Q1: Are You Manufactory or Trade Company?

We are the 100% Manufactory specialized in thermoforming indurstry for plastic disposable packaging over 10 years with 1,000 square meters workshop area, located in Huzhou, Zhejiang Province, which it's 2 hours by car from Shanghai Pudong Airport to our factory. You are warmly welcome to visit our factory.

Q2: What is the material you used? Is it food grade or eco friendly?

The main materials we used is PLA, PET, PP, PS, PVC, PC All the materials we used is food grade and eco friendly which pass ROHS, GRS, SGS,ISO9001,ect., EXCEPT PVC. PVC is not food grade materials. Mainly used to pack electronics and harware.

Q3: Can you provide OEM and ODM services?

Yes. About OEM, you can customize machine such as printing your logo on, color and packaging.

Q4: Is there quality control when manufacturing the lines?

A: Certainly, we have a group of team who will be responsible for quality control from laying off the raw material, processing the rollers and the other parts, making treatment on the roller surface and shaft, assembling, testing and packaging.

Q5: What's your strength comparing to the other supplier?

A: We'll supply you the best quality and service and provide you with good advice beyond your requirements. The lines are easily for installation with low maintenance requirements.